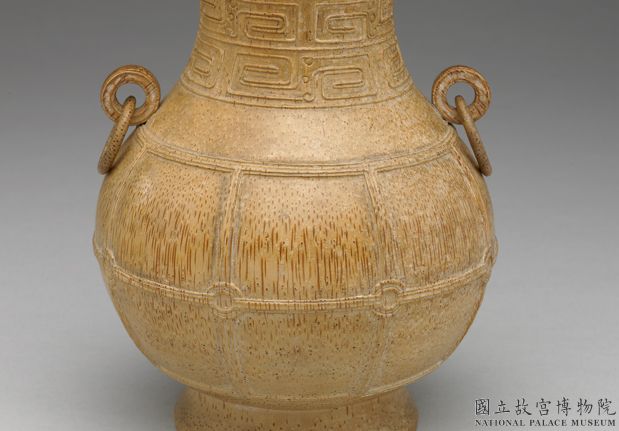

Period:Northern Song dynasty Production date:1086-1127

Materials:stoneware, copper,

Technique:incised, glazed,

Dimensions:Diameter: 277 millimetres Height: 88 millimetres

Description:

Ding stoneware basin, with copper-bound mouth rim. Creamy white. Carved and incised peony scrolls on interior and exterior.

IMG

![图片[1]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00441569_001.jpg)

![图片[2]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00441571_001.jpg)

![图片[3]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00441567_001.jpg)

![图片[4]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00365642_001.jpg)

![图片[5]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00365643_001.jpg)

Comments:Published PDF date : Northern Song 11thC-12thC Room 95 label text:PDF 102Basin with carved peonies and copper rimThis basin is incised with flowering peonies with combed textured petals. The base and foot are glazed. Between AD 1086 and AD 1127, Ding potters pioneered the technique of fushao 覆燒 (firing a vessel upside down on its rim). Kiln managers saved on fuel by firing a greater number of pots at one time, stacking them in stepped saggars. The disadvantage was the unglazed mouth rim, cleaned free of glaze to avoid the vessel sticking to the saggar. Craftsmen used sheet copper and occasionally gold or silver, cut to size and heated to fit the rims to hide this flaw. Historical accounts suggest that dressing the rim with metal actually enhanced the status of the clay vessel. Stoneware with carved decoration and transparent glaze and copper rimDing ware 定窯Quyang county, Hebei province 河北省,曲陽縣Northern Song dynasty, about AD 1086–1127 PDF 102 白釉刻劃牡丹纹镶铜口盆此盆以刻劃花牡丹紋為飾,花瓣紋理以篦劃手法展現。器底及圈足滿釉。1086年至1127年,定窯窯工們開創性地使用了將器物口沿向下放置燒窯的覆燒技術。窯工使用階梯式匣缽疊放器物,這樣一次燒窯可以燒造大量的器物,節省了燃料。但覆燒的缺點是,為了避免向下放置的器物口沿與匣缽粘連,口沿處須刮掉釉層,使之成為“芒口”。工匠們以銅片,偶爾也使用金或銀片,切割成合適的尺寸,加熱后包鑲在口沿上來掩蓋這一缺陷。史料記載表明,以金屬包鑲口沿事實上提高了黏土燒成品的地位。炻器,刻劃花,透明釉,鑲銅口定窯河北省曲陽縣北宋,約1086-1127年

Materials:stoneware, copper,

Technique:incised, glazed,

Dimensions:Diameter: 277 millimetres Height: 88 millimetres

Description:

Ding stoneware basin, with copper-bound mouth rim. Creamy white. Carved and incised peony scrolls on interior and exterior.

IMG

![图片[1]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00441569_001.jpg)

![图片[2]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00441571_001.jpg)

![图片[3]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00441567_001.jpg)

![图片[4]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00365642_001.jpg)

![图片[5]-basin BM-PDF.102-China Archive](https://chinaarchive.net/Northern Song dynasty/Ceramics/mid_00365643_001.jpg)

Comments:Published PDF date : Northern Song 11thC-12thC Room 95 label text:PDF 102Basin with carved peonies and copper rimThis basin is incised with flowering peonies with combed textured petals. The base and foot are glazed. Between AD 1086 and AD 1127, Ding potters pioneered the technique of fushao 覆燒 (firing a vessel upside down on its rim). Kiln managers saved on fuel by firing a greater number of pots at one time, stacking them in stepped saggars. The disadvantage was the unglazed mouth rim, cleaned free of glaze to avoid the vessel sticking to the saggar. Craftsmen used sheet copper and occasionally gold or silver, cut to size and heated to fit the rims to hide this flaw. Historical accounts suggest that dressing the rim with metal actually enhanced the status of the clay vessel. Stoneware with carved decoration and transparent glaze and copper rimDing ware 定窯Quyang county, Hebei province 河北省,曲陽縣Northern Song dynasty, about AD 1086–1127 PDF 102 白釉刻劃牡丹纹镶铜口盆此盆以刻劃花牡丹紋為飾,花瓣紋理以篦劃手法展現。器底及圈足滿釉。1086年至1127年,定窯窯工們開創性地使用了將器物口沿向下放置燒窯的覆燒技術。窯工使用階梯式匣缽疊放器物,這樣一次燒窯可以燒造大量的器物,節省了燃料。但覆燒的缺點是,為了避免向下放置的器物口沿與匣缽粘連,口沿處須刮掉釉層,使之成為“芒口”。工匠們以銅片,偶爾也使用金或銀片,切割成合適的尺寸,加熱后包鑲在口沿上來掩蓋這一缺陷。史料記載表明,以金屬包鑲口沿事實上提高了黏土燒成品的地位。炻器,刻劃花,透明釉,鑲銅口定窯河北省曲陽縣北宋,約1086-1127年

© Copyright

The copyright of the article belongs to the author, please keep the original link for reprinting.

THE END